Oscillators Can Be Used to Replace Short Supplies of Capacitors

(Image source: SiTime)

(Image source: SiTime)

With the current wait time for capacitors being a year or more, backlogs are forcing companies to extend timelines for new designs to get to market. According to industry experts, the shortage is expected to worsen before it gets better. There are some predictions that the capacitor shortage may continue to 2020 and possibly later. With a forecast like this, many companies are looking for new strategies that will reduce capacitor dependence. One solution is to use oscillators instead of resonators. This solution could also fix other design issues.

Below are three reasons supporting the replacement of quartz crystal resonators (XTALs) with oscillators and why this is a better solution.

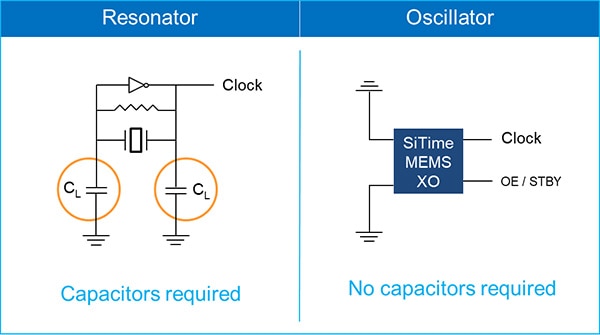

1) Resonators require load capacitors, oscillators don’t

Designs that do not need capacitors means there is no need to wait for parts.

Load capacitors are required in most resonators in order to provide phase shift and sustained oscillation. Conversely, oscillators combine a resonator and an oscillator IC with on-chip capacitance, into one package. This is done to ensure matching of the resonator and oscillator circuit and eliminates the need for tuning the resonate frequency with external capacitors. Additionally, if SiTime 32 kHz MEMS oscillators are used, there is no need for power supply decoupling capacitors.

(Image source: SiTime)

(Image source: SiTime)

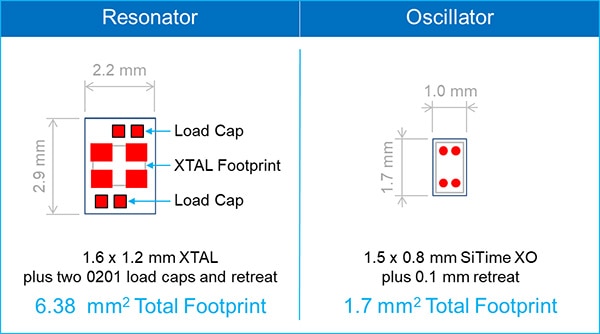

2) Oscillators require less board space

Looking at the smallest crystal resonator currently available and taking into account the capacitors that it requires, the total board space used is in excess of 6 mm2. Contrasting that with the smallest MEMS oscillator currently available, a total of only 1.7 mm2 of board space is used. This effectively shrinks the footprint to less than one-third the size.

(Image source: SiTime)

(Image source: SiTime)

Further reduction of the timing footprint and BOM can be achieved with the use of an oscillator because of the fact that it is an active circuit with an output driver that is capable of driving two to three loads depending on the drive strength. Because of this, a single oscillator can replace multiple crystals along with the capacitors associated with them.

3) Oscillators from SiTime are currently available

Without capacitors, which are currently in short supply and have long lead times, most resonators are useless. However, SiTime MEMS oscillators are available now in many frequencies, voltages, and stabilities within a wide operating range.

While specialized materials and processes are used to manufacture components such as capacitors and crystal resonators, SiTime MEMS oscillators are manufactured using standard semiconductor packaging and processes. By leveraging the infrastructure of the huge semiconductor industry – with its immense capacity, a multitude of vendors, many fabrication facilities, and compatible processes – an extremely robust supply chain for producing silicon MEMS oscillators is currently in place.

Furthermore, the architecture of SiTime oscillators is designed to be programmable. Large volumes of blank MEMS oscillators are produced, held in inventory, and are programmed to customer specifications. Therefore, manufacturing MEMS oscillators with standard processes and materials, combined with their programmability, results in enormous flexibility, massive scalability, and ultra-short lead times.

Pre-programmed SiTime oscillators are currently available at DigiKey today. If the desire is to instantly program parts in the lab, get a Time Machine II programmer and some blank oscillators to create custom parts.

More can be learned about the benefits of oscillators by reading SiTime’s white paper: The top 8 reasons to use an oscillator instead of a crystal resonator.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum