Best-in-Class Ergonomic Solutions for Industrial Environments

(Image source: Molex)

(Image source: Molex)

Through its distribution partner, DigiKey, Molex strives to help industrial automation customers increase efficiencies and safety by offering rugged, high-performing products such as Woodhead Wiring Devices, Cable Reels Power Distribution, and Portable Lighting Products.

Aero-Motive Balancers, Positioners and Retractors may not be the types of products most customers associate with Molex, but they also play a key role in improving operational efficiencies and worker safety. And they’re available through DigiKey.

Making Workers and Facilities Safer and More Efficient

Musculoskeletal disorders result from overexertion or repetitive motion, and they include soft-tissue injuries such as sprains, strains and tears. According to the U.S. Department of Labor, in 2016, manufacturing employees experienced 35,110 injuries due to sprains, strains or tears that resulted in days away from work. In addition to the pain and suffering such injuries cause individuals, companies are burdened with workers’ compensation costs and lost labor.

Ergonomic tool support products, such as Aero-Motive Balancers, Positioners and Retractors, can reduce injuries caused by repetitive motion and strenuous tasks common in manufacturing and assembly environments. They make tools virtually weightless and they eliminate the risk of operators dropping tools or tripping over them. Additionally, Aero-Motive Positioners make it unnecessary for workers to pick up and lay down tools, reducing repetitive motion injuries.

Aero-Motive Tool Support Products also increase operational efficiencies because they can speed up assembly processes and reduce physical stress on workers.

Whether it’s a positioner suspending a small screwdriver before an assembler at a contract manufacturer or a balancer making a 60 to 92 kg welding gun practically weightless, Aero-Motive products offer cost-effective, best-in-class ergonomics to a wide range of industries.

Balancers, Positioners and Retractors

While all three deliver ergonomic support to operators, the main Aero-Motive Tool Support products each have other purposes as well:

Balancers make tools and loads virtually weightless, enabling operators to work more efficiently and reducing fatigue, which will increase productivity.

(Image source: Molex)

(Image source: Molex)

Positioners use a friction break to hold a tool or object in a desired position, eliminating workers’ repetitive pickup/lay-down actions.

(Image source: Molex)

(Image source: Molex)

Retractors pull back tools or other objects when no force is applied to it, getting tools out of workers’ way when they don’t need them while keeping them easily accessible.

(Image source: Molex)

(Image source: Molex)

After you’ve chosen the Aero-Motive tool support product that will best serve your purposes, you’ll need to know the appropriate way to install them on your manufacturing floor or work area.

Achieve best-in-class ergonomics and safety with Aero-Motive Tool Support products in 5 easy steps:

1. Measure the total weight of the tool (including hoses, fluids, etc.) to find the weight of the load.

2. Choose the balancer, retractor or positioner that will put the total weight of the load at the midrange of the product’s published weight capacity.

3. Use a safety chain or a safety cable to secure the balancer or retractor to a separate trolley on runways.

4. Adjust the tension on the balancer or retractor using the external adjustment mechanism until the tool becomes weightless in an operator’s hand.

5. Monitor the integrity of the main cables and secondary supports on a daily basis.

Which Aero-Motive Product Is Right for Your Facility?

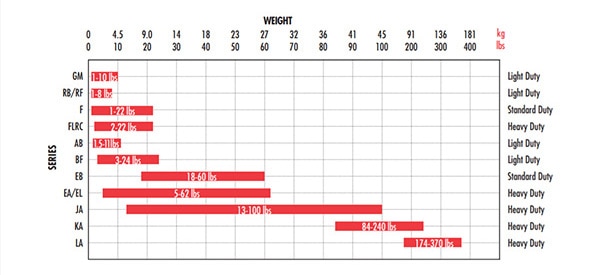

Aero-Motive Balancers, Positioners and Refractors come in different versions to meet the needs of a wide range of industries and applications. Whether the need is for general factory floor assembly, in an automotive body shop or power train assembly line, in a consumer/home appliance plant, or for electrical, medical, heavy equipment manufacturing, Aero-Motive has the effective ergonomic solution.

Below is a chart that indicates which Aero-Motive Series is appropriate for an application.

(Image source: Molex)

(Image source: Molex)

Aero-Motive Tool Support Products use a proprietary spring that outlasts and outperforms its competitors’ similar products. For superior durability in rugged industrial environments, Aero-Motive Balancers, Positioners and Retractors are well known for providing best-in-class ergonomics and are built for long-lasting reliability.

Why risk injury or inefficiency when you can employ the benefits of Molex Aero-Motive Tool Support Products?

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum