Arc Flash at Google Data Center Underscores Need for Protection: Here’s Where to Start

An arc flash at a data center, industrial facility, or large renewable energy sites—such as a wind or solar farm—can be a dangerous event. Three people were injured by a recent arc flash at a Google data center in Council Bluffs, Iowa1. An arc flash creates an electrical explosion and generates heat at temperatures up to 19,000 degrees centigrade (C). For perspective, that’s hotter than the surface of the sun.

While arc flashes have long been a serious concern, it was only in January 2020 that the National Electric Code (NEC) was updated to include protection from them. An arc energy reduction requirement for circuit breakers rated at 1200 amperes (A) and higher was added. A key element of the updated NEC requirement is that arc flash protection equipment must be used when the clearing time of the fuse on the circuit is less than 0.07 seconds (s). Even if fuses are properly rated, an additional layer of protection, such as an arc flash protection relay, is often employed due to the risk of significant injury.

With that in mind, let’s discuss the dynamics of arc flash, review the requirements of the U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA), compare bolted faults with arc faults, briefly present IEEE arc flash hazard calculations, and look at several arc flash protection scenarios and related protection relays from Littelfuse.

OSHA requires that equipment operating at 50 volts or more be evaluated for arc flash protection. The evaluation determines the safety boundaries (prohibited, limited, and restricted access) and identifies what personal protection equipment (PPE) must be worn. When evaluating arc flash potential and related safety measures, it’s necessary to differentiate between bolted faults and arc faults.

Bolted vs. arc fault current

In systems rated for less than 1,000 volts, a bolted fault is defined as a fault with zero impedance. Arc fault current is defined relative to the impedance of the arc. Protective devices in these systems must be set to trip for the higher, more serious bolted fault current.

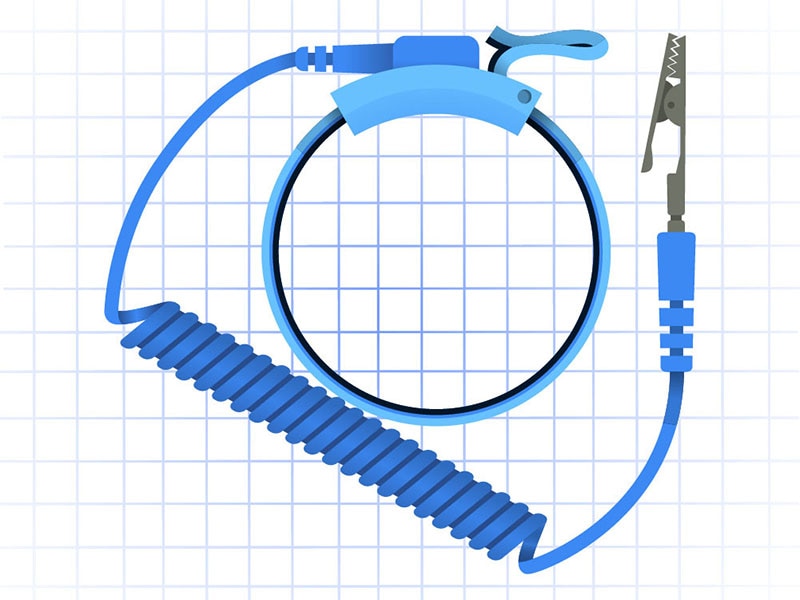

Protective device clearing time is also important. There are tradeoffs between faster clearing, safety, and system operation. Faster tripping can enhance personnel safety. However, if the system includes several protective devices, faster tripping can prevent coordinated operation of the devices and result in a larger negative impact on the overall facility. Microprocessor (MPU) based arc fault relays provide inherently fast reaction times and can be used to trip circuit breakers to speed arc flash protection while supporting coordinated operation to minimize disruption across the facility (Figure 1).

Figure 1: To speed reaction times to fault conditions, an arc fault protection relay can be used to trip a circuit breaker (CB). (Image source: Littelfuse)

Figure 1: To speed reaction times to fault conditions, an arc fault protection relay can be used to trip a circuit breaker (CB). (Image source: Littelfuse)

IEEE arc flash hazard calculations

Arc flash hazard calculations based on IEEE 1584-2018 are commonly used in industrial settings to meet OSHA regulations. IEEE 1584 can predict arc currents and incident energy levels, thereby identifying the necessary PPE and defining safe working distances. It uses an empirically derived model based on parameters such as:

- 208 to 15,000 volts alternating current (VAC), three-phase, with frequencies from 50 to 60 Hertz (Hz)

- 700 to 106,000 amp bolted fault currents

- Common equipment enclosure sizes and grounded or ungrounded conductor configurations

- Gaps between conductors and faults involving all three phases

Switchgear protection

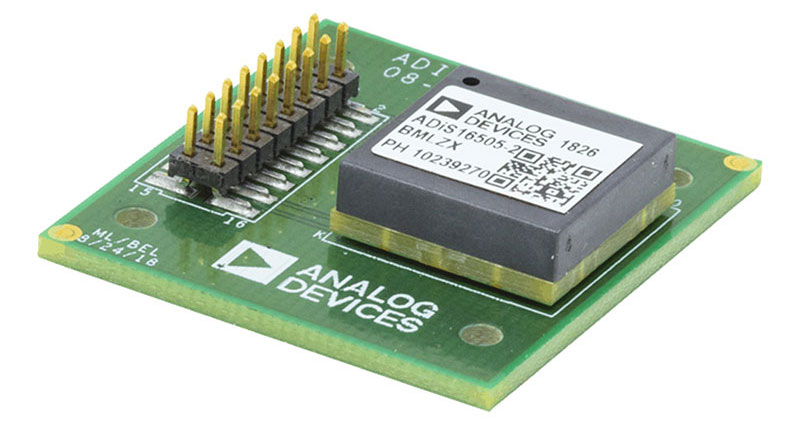

The PGR-8800 series from Littelfuse can be used by facility designers to provide switchgear protection. The PGR-8800-00 (Figure 2) is an MPU-based relay that can monitor switchgear cabinets with a PGA-LS10 line-of-sight point sensor, providing arc flash protection and fault location identification. In addition, the back bus bar can be monitored by a PGA-LS20 or PGA-LS30 fiberoptic sensor. The PGR-8800-00 senses the light from an arc flash in less than 1 millisecond (ms). It includes an adjustable trip threshold to compensate for ambient light conditions and to minimize nuisance tripping.

Figure 2: The PGR-8800-00 can use a variety of sensors to identify an arc flash occurrence in less than 1 ms. (Image source: Littelfuse Inc.)

Figure 2: The PGR-8800-00 can use a variety of sensors to identify an arc flash occurrence in less than 1 ms. (Image source: Littelfuse Inc.)

Protecting generators

The AF0100 arc flash relay from Littelfuse can be used for generator protection. It’s designed for use with PGA-LS20 / PGA-LS30 optical sensors and PGA-LS10 point sensors. It can turn off the generator and trip its breaker, disconnecting the faulty device from the utility. It’s designed to operate in high-vibration and space-constrained environments.

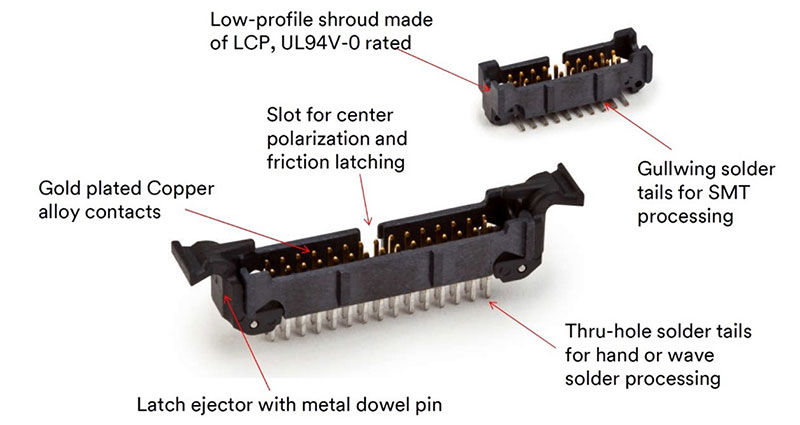

Multi-zone protection

Facility designers can combine several AF0500 relays to cover multiple zones with unlimited scalability. In addition, AF0500 relays can connect with lower-cost AF0100 relays to optimize the cost/performance tradeoffs in multi-zone arc flash protection systems (Figure 3).

Figure 3: AF0500 relays can be used alone, in combination with other AF0500 relays, and with AF0100 relays to optimize the performance of multi-zone installations. (Image source: Littelfuse)

Figure 3: AF0500 relays can be used alone, in combination with other AF0500 relays, and with AF0100 relays to optimize the performance of multi-zone installations. (Image source: Littelfuse)

Conclusion

Both the NEC and OSHA recognize the dangers associated with the occurrence of an arc flash and have requirements that must be followed in industrial settings. IEEE 1584 is commonly used to assess the potential for arc and bolted flash current levels and determine the necessary protection. As shown, arc flash protection relays are available and can be used to provide enhanced protection in a range of application scenarios.

Reference:

1: Incident at Google Data Center Highlights Risks of Arc Flash

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum